| You are here :Home - Product |

| Control theory and action description on Air Processor |

|

|

Control theory and action description on air processor

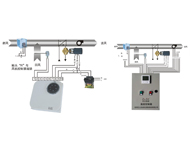

◆ System Control : the figure system is the two-three way valves and each driver that applied to two-pipe cold/hot water air compressor control system, this system is mainly composed of proportional plus integral temperature controller, temperature sensor installed in return duct, electric control valve and driver, the controller is to compare the temperature tested by sensor with temperature set by controller, and output correspond pressure signal according to comparison result, as to control the electric control valve, keep the blast temperature within setting range. The transfer switch of the system is changed from winter to summer.

◆ Summer Cooling : When the room temperature detected by the sensor is higher than set temperature, the electric control valve opens, the flow rate increases ; Conversely, When the room temperature detected by the sensor is lower than set temperature, the electric control valve closes, the flow rate decreases.

◆ Winter heating : When the room temperature detected by the sensor is lower than set temperature, the electric control valve opens, the flow rate increases; Conversely, when the room temperature detected by the sensor is higher than set temperature, the electric control valve closes, the flow rate decreases. R contactor could be linked with the fan, when the fan starts a new air damper opens, the temperature controller power is turned on, the whole system is under controlled; when the fan power is cut off, the fan stops running, and the new air damper closes. |

|

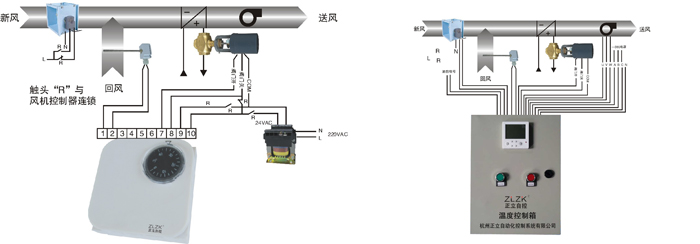

Control theory and action description on air compressor group (with control box)

◆ System Control : Summer Cooling : Convert switch to " summer ", when the temperature detected by the sensor is higher than set value, the electric control valve runs by way of proportional plus integral, the flow increases, conversely, when the temperature detected by the sensor is lower than set value, the electric valve runs by way of proportional plus integral, the flow decreases; winter heating: Convert switch to " winter ", when the temperature detected by the sensor is lower than set value, the electric valve runs by way of proportional plus integral, the flow increases; contrary, the flow decreases .

◆ Fan control:

A. when the fan power is small, you can start directly.

B. when the fan power is big, in order to avoid affecting the normal operation of other electrical equipments, adopt Y-△ to start.

C. variable voltage control and frequency control are available. In addition, fans links with fire.

◆ Damper Control: damper fully opens or closes, links with fan.

◆ Fire Control: Fire can receive signals from the fire control center.

◆ Linkage control : when centralized control box receives fire signal, the fan stops running, simultaneously, electric valve and fan valve close at the same time , when the fan starts, electric valve and damper start.

◆ Centralized control box : panel has functions of power supply, fan working, fan failure, fire and other display, fans start, stop and summer & winter system conversion. The system has thermostat, transformers and auxiliary electrical equipment installed in the control box , which greatly facilitates wiring installation. | |

|

|

|